THE SCIENCE OF EXTREME COLD

Cryogenics is the field of technology focused on producing, storing, and applying materials at ultra-low temperatures, typically below -160°C. At OPW CES, high-quality cryogenic solutions are foundational to clean energy, life sciences, and aerospace innovation.

WHAT IS CRYOGENIC TECHNOLOGY?

Derived from the Greek word “Kryos” (cold), cryogenics involves the liquefaction of gases for transportation, storage, and specialized industrial use. Key cryogenic gases include:

- Liquid nitrogen (LN₂)

- Liquid oxygen (LOX)

- Liquid hydrogen (LH₂)

- Liquid helium (LHe)

- Liquid argon (LAr)

Each gas liquefies at a specific temperature—helium at -269°C, oxygen at -183°C—requiring precise engineering and handling.

HOW ARE CRYOGENIC TEMPERATURES ACHIEVED?

Cryogenic systems use several physical methods to reach ultra-cold states:

- Thermal Conduction – Transfers cold from cryogenic liquids to surrounding materials

- Evaporative Cooling – Uses energy loss from liquid-to-gas phase change

- Joule-Thompson Expansion – Cools gases through rapid pressure drops

- Adiabatic Demagnetization – Cools using energy-absorbing paramagnetic salts

These techniques enable applications such as superconductivity, liquefied natural gas (LNG) storage, and hydrogen fueling infrastructure.

OPW CES: LEADERS IN CRYOGENIC INFRASTRUCTURE

With brands like Demaco, CPC Cryolab, and Acme Cryogenics, OPW CES brings together a legacy of cryogenic expertise. Our capabilities include:

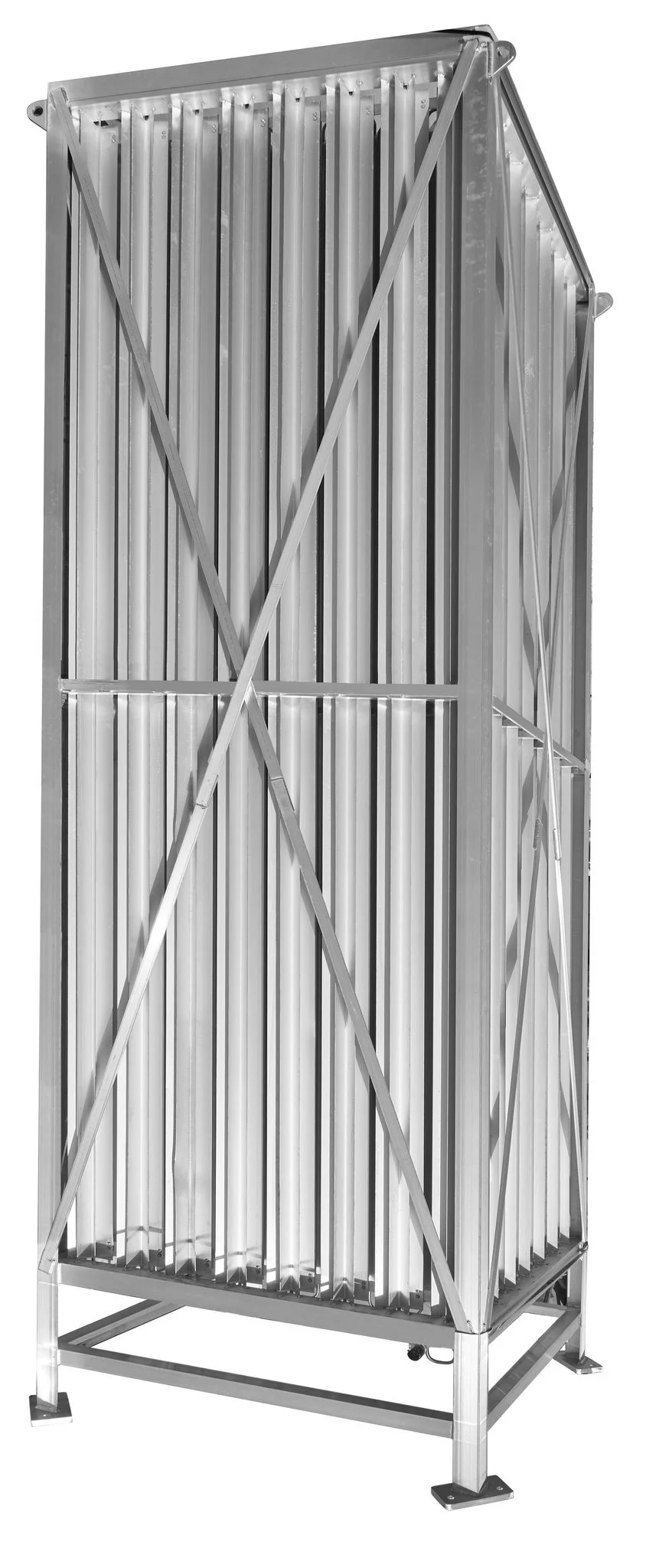

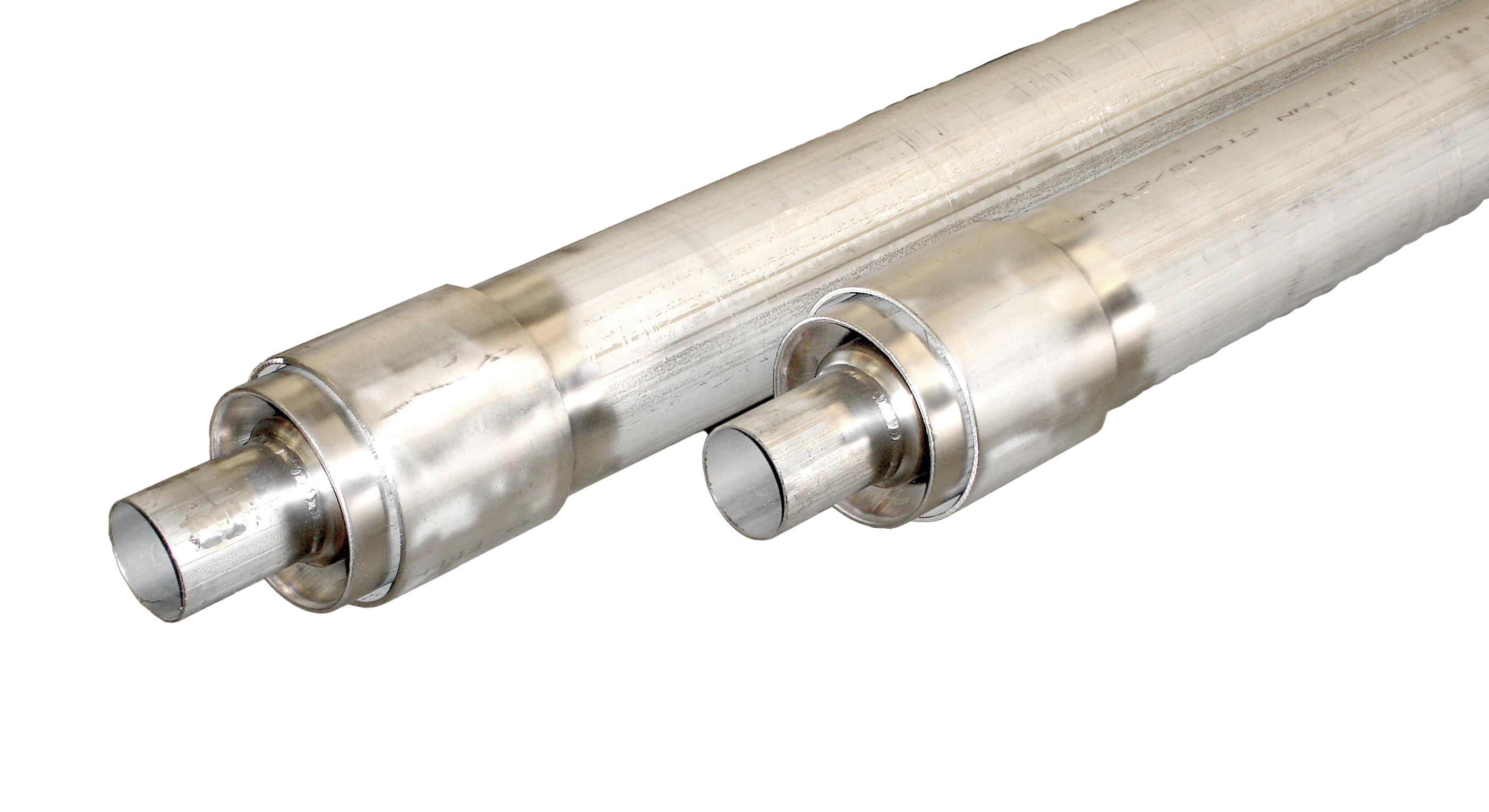

- Cryogenic vacuum-insulated pipelines

- Custom valve design for hydrogen and helium systems

- Certified production and cleanroom testing

- Global project management and support

EXPERT BRANDS DRIVING CRYOGENIC INNOVATION

OPW CES COMBINES CRYOGENIC LEADERSHIP FROM MULTIPLE SPECIALIZED BRANDS:

- Demaco: End-to-end cryogenic infrastructure engineering

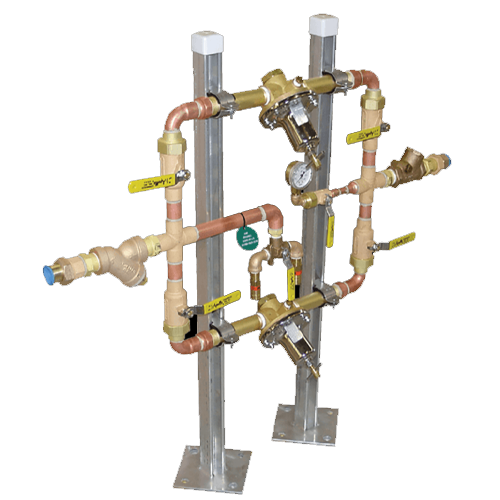

- CPC-Cryolab: Ultra-cold valves and manifolds used in helium, hydrogen, and nitrogen systems

- SPS Cryogenics: Long-distance vacuum-insulated pipeline manufacturing

- SGS: Gas delivery and alarm systems in cleanroom and R&D environments

- Acme Cryogenics: On-site installation, maintenance, and repair of cryogenic systems

- RegO Products: Cryogenic safety valves and control components that meet global codes

Want to learn more about our solutions for cryogenics?

Explore our Products or Contact Us to speak with a specialist.

Cryogenics 101: Understanding the Science, Applications, and Safety of Ultra-Cold Technologies”

THE HISTORY OF CRYOGENIC TECHNOLOGY

MORE AND MORE LIQUID GASES EMERGE

By the 19th century, cryogenics became more widely known, as by then more and more gases could be successfully liquefied.

It all began back in 1877 when Callietet and Pictet succeeded in liquefying oxygen. Experiments were in full swing around that time, and soon liquid versions of other gases appeared. For example, in 1884, hydrogen was the first gas to be converted to mist. In 1862, Sir James Dewar developed a vacuum-insulated vessel to store cryogenic liquids, making it easier to work with liquefied gas. In the following years, experts succeeded in liquefying an increasing number of gases, including the last in line, helium. The liquid form of this gas was first used in 1908.

CRYOGENIC TECHNIQUES ACROSS A VARIETY OF INDUSTRIES

Meanwhile, more and more industries discovered the usefulness of cryogenic technology. In 1961, for example, cryosurgery was first practiced in the United States. Scientists found that slow cooling could destroy unhealthy human tissue. In the United States, liquid nitrogen was used for this purpose, and a few years later, physicians in South Africa also used the method there. In South Africa, however, nitrous oxide was used instead of liquid nitrogen.

The aerospace industry also introduced cryogenic technology in the 20th century. In 1961, the American Atlas-Centaur rocket used liquid hydrogen and liquid nitrogen for the first time in the space program. This event is considered a significant milestone in cryogenics and immediately led to large-scale liquid hydrogen production for similar projects.

The medical and aerospace industries are just examples of sectors where cryogenic technology has been in use for a long time already. Cryogenics has also, for a long time, taken a prominent role in scientific research, the marine industry, and the mass production of liquefied gases in air separation units.

PRODUCTS

CHOOSE OPW FOR CRYOGENICS

EFFICIENCY IN GAS HANDLING

Our technologies optimize industrial gas production and distribution for enhanced efficiency.

ENVIRONMENTAL SUSTAINABILITY

We champion eco-conscious practices within the Industrial Gas and cryogenics industry to reduce environmental impact.

SUSTAINABLE CRYOGENIC SOLUTIONS

Our products and solutions enable the industry to operate with a reduced carbon footprint while maintaining precision and reliability.

EXPLORE OUR OTHER INDUSTRIES

HYDROGEN

High-quality cryogenic solutions are pivotal in driving the growth of liquid hydrogen as a clean and sustainable energy source for diverse applications, including transportation, industrial, and residential/commercial fueling.

INDUSTRIAL GAS & CRYOGENICS

As a foremost provider of mission-critical cryogenic products and services, we lead the way in enabling the production, storage, and distribution of cryogenic liquids and gases. We are committed to forging a path toward a greener and more sustainable future.

LIQUIFIED NATURAL GAS (LNG)

LNG represents a promising frontier in the global transition to high-quality, cleaner energy solutions. We not only embrace this potential but also pioneer advanced solutions that cater to the current needs while proactively addressing future challenges.

Need More Information?

Customer Support

Reach Out to Our Customer Support Team for Prompt Assistance and Answers to Any Questions or Concerns You May Have

Technical Support

Contact Us for Technical Support on Your Projects and Resolving Any Technical Issues You Encounter

Contact a Distributor

Locate a Nearby Distributor for Replacement Parts

Product Enquiry

Product Information request form to find the right solution

Need More Information?

Customer Support

Reach Out to Our Customer Support Team for Prompt Assistance and Answers to Any Questions or Concerns You May Have

Technical Support

Contact Us for Technical Support on Your Projects and Resolving Any Technical Issues You Encounter

Request a Quote

Request a Quotation for Your Project or Part to Find the Right Solution